R Wind

Chirping

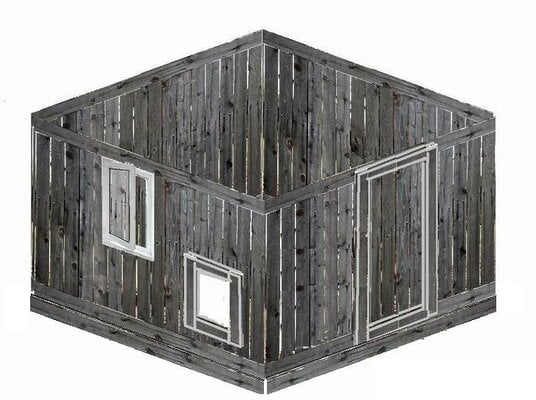

We're new to chickens, building a first 6.5x8ft coop with walls of old cedar fence panels. (Extremely well worn, 30 years old. I don't think cedar oil will be a problem at this point. )

We're trying to build this with materials on hand for the most part. We're screwing this together with brackets at corners and floor, because we're thinking we'll move soon and want to disassemble the panels and take it all with us in a pickup truck.

We've gotten to the roof system, and I'm thinking -- in aide of light weight and movability -- that we'll build:

-- an extension above the front wall;

-- build similar triangular sections above the side walls;

-- cover all with hardware cloth.

And then rather than rafters, make a sloped roof/ flat platform atop those open-air sections, made of a cattle panel. Should be stiff enough.

We have a source of inexpensive polycarbonate wavy roof panels. Does anyone have an idea for attaching the poly to the top of the cattle panels? (We know we could add purlins but it adds weight and cost.) We've not worked with polycarbonate roof panels before.)

More details below. Would appreciate suggestions. Thanks!

-------------

So far the floor and walls are in:

Concrete block piers.

Two large heavy-duty pallets with 10" wide oak floor boards.

Plan to cover the floor with a layer of 1/8" fiberglass wall paneling for washability.

Four walls of the old fence panels (on three rails).

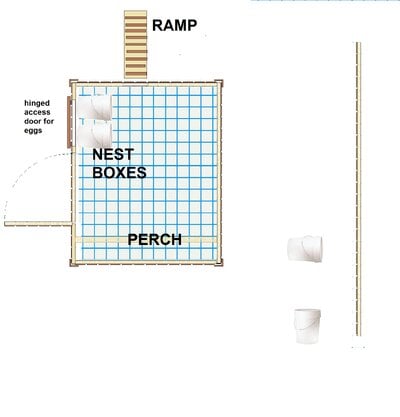

People door on one side; chicken door on another. I have a layout and concept drawing.

It's under elm and oak trees; should be shaded. We have, hot humid Summers, a few cold spells in winter not too often down into the teens. (But we do occasionally have a colder spell, such as the 2F abnormality this year.)

I'll also need suggestions on ventilation. We'll have to add one or more windows. Not decided where to place them yet.

There are sizeable gaps between the old fence boards. We thought on the bottom 30 inches (up to the middle rail) to add battens to stop drafts. On the top two feet between rails we are planning on stapling hardware cloth, allowing that extra bit of ventilation.

We're trying to build this with materials on hand for the most part. We're screwing this together with brackets at corners and floor, because we're thinking we'll move soon and want to disassemble the panels and take it all with us in a pickup truck.

We've gotten to the roof system, and I'm thinking -- in aide of light weight and movability -- that we'll build:

-- an extension above the front wall;

-- build similar triangular sections above the side walls;

-- cover all with hardware cloth.

And then rather than rafters, make a sloped roof/ flat platform atop those open-air sections, made of a cattle panel. Should be stiff enough.

We have a source of inexpensive polycarbonate wavy roof panels. Does anyone have an idea for attaching the poly to the top of the cattle panels? (We know we could add purlins but it adds weight and cost.) We've not worked with polycarbonate roof panels before.)

More details below. Would appreciate suggestions. Thanks!

-------------

So far the floor and walls are in:

Concrete block piers.

Two large heavy-duty pallets with 10" wide oak floor boards.

Plan to cover the floor with a layer of 1/8" fiberglass wall paneling for washability.

Four walls of the old fence panels (on three rails).

People door on one side; chicken door on another. I have a layout and concept drawing.

It's under elm and oak trees; should be shaded. We have, hot humid Summers, a few cold spells in winter not too often down into the teens. (But we do occasionally have a colder spell, such as the 2F abnormality this year.)

I'll also need suggestions on ventilation. We'll have to add one or more windows. Not decided where to place them yet.

There are sizeable gaps between the old fence boards. We thought on the bottom 30 inches (up to the middle rail) to add battens to stop drafts. On the top two feet between rails we are planning on stapling hardware cloth, allowing that extra bit of ventilation.