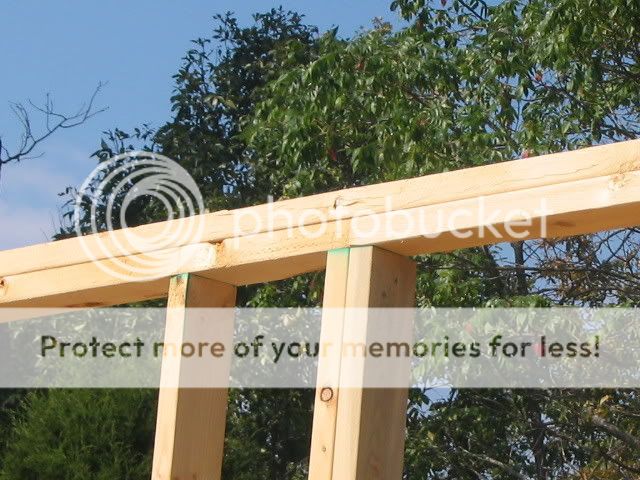

Coop looks like it will be great!!!

I am contemplating running water and electricity to my coop. In regard to the flooring...I bought some cheap linleum remnants from Lowe's and glued them to my plywood floor. It works great with deep litter and makes clean-up real easy.

It's a shame you had to retire so young due to health reasons...it seems like you have the energy and skills for construction or carpentry...

I am looking forward to my retirement years...

I am contemplating running water and electricity to my coop. In regard to the flooring...I bought some cheap linleum remnants from Lowe's and glued them to my plywood floor. It works great with deep litter and makes clean-up real easy.

It's a shame you had to retire so young due to health reasons...it seems like you have the energy and skills for construction or carpentry...

I am looking forward to my retirement years...