Here it is, thanks to @gtaus :

https://www.backyardchickens.com/threads/fuzzis-chicken-journal.1550586/page-9#post-26452472

https://www.backyardchickens.com/threads/fuzzis-chicken-journal.1550586/page-9#post-26452472

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Ah, thank you.

12 feet long is a decent length, I'll have to think about it.

Thank you for the panel suggestions, I'll shop around and see what I can find.

What do you mean by a rebar? Do you have pictures you could show me, or do you mind taking a few when you have time? How do you have the top so water doesn't pool on top?

OOps forgot to add this image to show how the corner bracing connects.12 feet long is a decent length, I'll have to think about it.

Thank you for the panel suggestions, I'll shop around and see what I can find.

What do you mean by a rebar? Do you have pictures you could show me, or do you mind taking a few when you have time? How do you have the top so water doesn't pool on top?

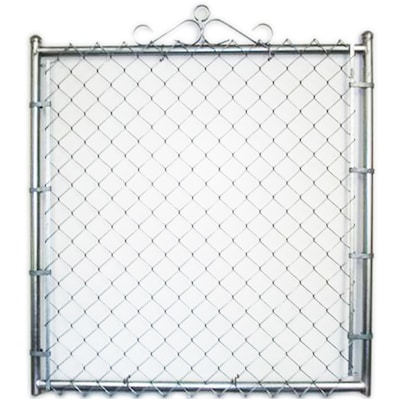

Sorry, been meaning to reply, but haven't been able to figure out how to ask it.You use these (shop around for bet price, most likely will be sold where you buy the panels.)

They can be cut down to size however I think doing that would be the waste of money.Sorry, been meaning to reply, but haven't been able to figure out how to ask it.

Do you know if it's possible to do similar panels from the chain link fence posts you can buy from a fence supply business?

The panels are nice, but I'm wanting something shorter and the panels can not be cut down to size (thus a waste of money)

I think terminal posts and rails can be cut to length, or am I wrong?