The Palace Chicken Coop

When my wife brought home 5 fluffy new friends in July of last year, I knew a chicken coop was in our future. I also wanted to design and build it myself as a fun exciting project. Little did I realize that 5 months go by very quickly when you move into a new house!

When I first started doing research on our new coop I spent a great deal of time on BYC looking for ideas and suggestions. I owe a great deal of credit to the following coop's as they formed the basis of my plans.

- Wichita "Cabin Coop"

- Cptbahama's Chicken Coop

- The Taj Mahal

- The Builtmoore Coop

- The Red Roost Inn Chicken Coop

All of them gave me ideas and inspiration. We are grateful for their willingness to share their passion and work. Our girls would not have such a lovely home if it were not for the sharing of these and other people here on BYC!

In that spirit, I wanted to create a pictorial showing how we made our coop. If you have any questions on how something was done, please ask and I will try to answer to the best of my ability.

Design Phase

We wanted to make sure our coop met the following requirements:

- It had to be aesthetically appealing as it would be highly visible.

- Easy cleaning and maintenance (including being able to stand inside & have easy access to clean coop).

- Sturdy to handle those occasional tropical storm conditions here in Florida.

- Designed to use Deep Litter Method in coop and run.

- Resistant to Summer Rain Flooding that occurs in that part of the yard.

- Good ventilation and air movement.

- With adequate room for 5-7 hens (I figured we would be adding one or two later ).

I probably spent the better part of two weeks of late night web surfing to gather ideas and develop a plan of attack. I checked, double checked and cross referenced everything from space per bird requirements, DLM, nesting box sizes, roost length, building codes, roofing solutions, predator proofing, waterproofing, drainage ideas, to working with concrete and explosive nailers. I must admit the internet is a wonderful tool.

At this point I would like to add my *** Disclaimer ***: I am not, nor have I ever been an architect nor structural engineer. The plans and designs I created are from my understandings of things required to meet the objectives of my coop. They have not been approved by a certified engineer to meet certain hurricane, earthquake, volcanic, flooding, nuclear blast or other natural disaster sized forces. While every effort to make a safe environment for our chickens, some things may have been overlooked as we are novice chicken coop builders. Please note that no chicken was harmed during the making of this coop and all testing was done in very controlled manner were no chicken was ever placed in danger.

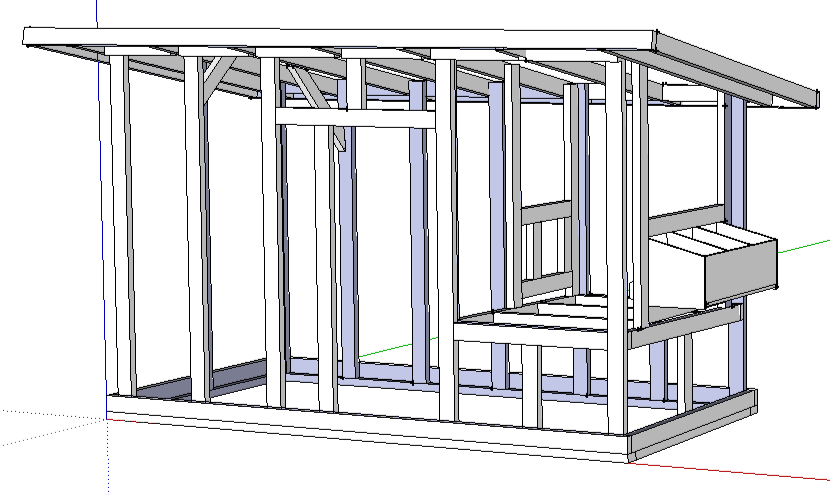

I must admit I spent a fair amount of time looking for plans online. It seemed I was unable to located any free plans that seemed to meet what we needed. So I decided to use Google's 3D modelling tool SketchUp to create a working model for our coop. It allowed me to spin the diagram in any direction and adjust it as I saw fit. It did take a while to get used to it, but the time spent in the learning curve was more than worth it during the construction phase. I can send you two files from SketchUp with the plans for the coop if you are interested. The first is the rough framing, while the second is the finished framing after the hardware cloth is installed. Please leave a comment or send me a private message and I will email them to you.

Or click here for a zipped file containing the SketchUp data files.

I decided on the following features for our coop:

- 5 - 7 egg laying hens (standard size)

- 10 sq ft of run space per bird

- 3 sq ft of coop space per bird

- 1 ft of roost rail per bird

- 1 nesting box per 3 birds

- sloped coop and nesting box floors for water drainage during clean outs

- sloped metal over wood roof that added stability as well as way to gather rain water.

- minimum 6 ft height so I could stand up inside.

- strength of construction to ensure durability and stability

- easy access doors for cleaning as well as egg harvesting

- raised foundation to help prevent flooding

- 1/2" hardware cloth used for screening

The entire structure is 12 ft by 6 ft. The coop measures 4 ft by 6 ft. The roof has a 1 ft overhang on all sides which gives us a 14 ft by 8 ft roof. The coop floor is approximately 30 inches above the run floor.

Foundation Phase

One of the biggest concerns I had was dealing with the potential flooding of the area surrounding the chicken coop. This past summer we had so much rain that the ground in the area became completely saturated. The ground was like a sponge and when you walked on it, you would sink an inch and water would flow around your boots. There was a concrete pad already poured where we wanted to build the coop, but we wanted to use that for a future shed or work area for the garden that is part of the same area. I made the decision to pour a footer attached to the existing pad to build the coop up on. This would raise the coop about 6 inches higher leaving room for drainage, even if the ground became completely saturated again.

It's important during this step to make sure everything is square and level. After framing the footer I added rebar and drainage stones to help facilitate water flowing out of the chicken coop.

I mixed and poured the concrete using a mixer rented from Home Depot. If you're wondering, the footer was 6 feet wide by 12 feet long and 6 inches across. The 24 linear feet took over 1/2 ton of concrete. Mix it with a mixer, or better yet, call a concrete company and have them deliver your required concrete premixed. My back was sore for a few days.

When I went to remove the forms, I noticed this in the concrete.

It seems my wife let the chickens out some time after I poured the cement and it had cured sufficiently. I found the guilty party not to far away. Even to this day she is claiming her innocence and blames it on Chicken Little.

Before I poured the concrete I had inserted a four foot section pvc pipe on the lowest part of the coop. I cut, drilled and assembled pvc pipe to act as a drain if a sever downpour occurred. The holes are about 2 inches apart.

Another view of drainage system.

I ordered a 1/2 cubic yard of gravel and a cubic yard of sand from a local aggregate company. They were kind enough to deliver it right to my driveway much cheaper than buying a huge number of bags at the local home improvement store (not to mention the numerous trips it would have taken to carry the weight). I used the gravel to build up the floor of the coop. Later it will be covered with weed prevention cloth and then the sand will be added. This put the "floor" of the coop at least six inches higher than the surrounding ground. Hopefully this will keep the ladies' feet dry.

Framing Phase

Framing was new to me. I had a general idea on how things were supposed to go, but no real framing experience. I did spend some time looking for nailing requirements and and how best to secure the coop to the foundation. During this research I came across a great deal of information on basic framing. I printed out images from the sketch-up and used them as a reference to cut all of the framing pieces. After cutting, the family pitched in to help pre-stain all the pieces. We used a good water sealant stain and made sure we had good coverage on all the pieces, especially the ones that would have direct contact with the concrete.

I was fortunate enough to have family help stain the wood.

The process of cutting and staining all the pieces took much longer than anticipated. Painting or staining after assembly might have been easier and faster. Might be something to consider.

Framing took several days. Keep in mind if you are working by yourself use numerous clamps and braces to keep everything where it is supposed to be.

After getting the initial walls and roof beams up, I used a powder activated nailer to secure the kick plates to the concrete putting a fastener about every foot. Probably more than I needed, but I was enjoying the process so a few extra fasteners never hurt. I had to vary the loads of powder if I was nailing into the concrete pad or the footer.

And another view from the opposite side. From this angle it is a little easier to see the coop floor is tilted towards the side where the door will go.

I cut the coop floor from plywood and then started installing the 1/2" hardware cloth.

It's a pretty straight forward job of measuring, cutting and then installing the hardware cloth. I used an automatic stapler to secure the cloth to the framing. Later it will be sandwiched between the framing and the finish framing piece. An automatic staple gun is an absolute must during this phase.

I then installed the finish framing pieces that were designed to hold the cloth in place.

These pieces help secure the cloth on the inside of the coop.

I also installed the roof sheathing at this time to help keep some of the rain out. I left some of the finish framing pieces off till after installing the walls.

Framed out where the hen door was going.

And also the nesting boxes. The boxes themselves measure about 14 inches across, 16 inches tall and 12 inches deep. You can't tell from the picture, but the floor of the nesting boxes is tilted towards the coop so water will flow out when cleaning. Notice the gap between floor of nesting box and the retaining board. You can also see the sloped coop floor pretty well in this picture. Also note that the nesting boxes are up about 6 inches off the floor to allow for the DLM.

General Construction Phase

I picked up some very inexpensive vinyl flooring tiles from the local home improvement store. They were quick and easy to install and hopefully will help when cleaning out the coop.

Here is a picture of the removable stopper blocks.

And with them removed as if we were cleaning the coop out.

Built and mounted the main access door.

Other side.

I also built the access ramp.

It is secured using four eye bolts. The two on the bottom of the ramp have been cut using a hack saw to make hooks. The ramp can be removed and washed off with a hose. I didn't install this till after I had the walls up on the coop, but I wanted to show it to you here.

Coop Phase

The coop walls are built with simple siding sheets found at Lowes. They are shiplap boards that have an overlapping edge on them. I decided to build the panel, install them on the coop, trim and then stain the boards. Most of the trim pieces are 1 x 4 strip. I choose the strip over the normal 1 x 4 boards because they were much cheaper and already had the rounded edge. Surprisingly the strip boards actually very few knots and were fairly straight. I had to cut two of the finish framing pieces to install the ventilation and siding above the coop door. I had forgotten the roof would hang down and interfere with the door opening. Using a skill saw set at the appropriate depth this wasn't a major issue.

I also secured a 2x4 to act as my door stop as well as my support for the siding. The ventilation holes were created using a 2" hole saw and covered with 1/2" hardware cloth.

Next, I built the coop door and trimmed it.

Here is a close up of the back of the door showing the hardware cloth sandwiched between siding and trim pieces.

Then installed it on the coop.

Then the same process for the rest of the sides.

Back coop wall installed.

Nesting box side.

Chicken ramp side wall.

Stained inside and out. Seems my son decided he liked to pretend he was a hen checking out the new coop.

Here is the outside stained.

Built the nesting box cover out of siding and some trim pieces I had laying around. I used an extra trim piece that will attach to the wall to create an overhang. Hopefully this will help reduce or eliminate water leaking into the coop from the nesting boxes. I will also put weather sealing around the rim to help make it water tight. There is also a lip on the bottom of the siding around the nesting boxes, but it might be hard to see in these pictures.

Painted and installed the nesting box lid.

Installed the missing finish framing pieces under the coop. This is a good view of where the concrete pad and footing are connected. Using the pre-existing pad helped reduce the amount of concrete in this project. The coop height also gives the chicken's adequate headroom.

Installed the rest of the hardware on the coop.

Run Floor Phase

I put weed block cloth down to prevent weeds from growing up through the floor and more importantly, preventing the sand from washing down through the rocks. It will also allow water to seep through into the drainage system.

Put sand around the edges to hold it in place.

Then I moved this cubic yard of sand...

Into the coop. In the end I think I ended up with a little less than 6 inches of base sand on top of a four inch rock base.

Roof Phase

Built and painted gutter. At fourteen feet, the gutter was going to be multiple pieces. It was pretty straight forward as far as assembly goes, but it did give me reason to pick up a pop-rivet tool. I always enjoy picking up new tools!

Installed it on the edge of the coop. I debated about building wedges to make the gutter parallel with the ground, but decided the 10 degree difference between roof and ground could be accounted for in the mounting. When I mounted the gutter to the coop I realized the lower end would be below the drip edge from the roof. I cut a piece of aluminum from the unused portion of gutter and painted it. It was installed overlapping the back of the gutter but will be under the drip edge from the roof.

Then I papered the roof and put down the 1x4 stripping to give breathing room.

Following a suggestion from this post on how to install a metal roof, I laid the metal roof out on the lawn to determine where the ribs would be in comparison to the edge of the roof would be. I trimmed the roof on both side to ensure I would not have a rib where the edging would be.

Then installed to roofing on the coop. If you have never installed any type of roofing, plan for some extra time in this step. Be careful and think safety. Winds can be dangerous when handling these large metal sheets and the edges are very sharp.

Finishing Details

The final stretch was finishing the nesting boxes and installing the roost bar. The chickens seemed to enjoy the temporary bar I was using for their roost, so I rounded the edges a little and left it unstained. No real reason why, I just liked it that way. I also think it was easier for the chickens to see. Seems they were having trouble accurately judging a stained one I had in there during hours of low light.

I used some trim pieces to give the nesting boxes a little more cozy feel. I pretty sure the girls didn't care one way or the other, but I liked them this way.

Here's a view from the outside showing the trim pieces. My wife and kids added the fake wooden eggs to give the girls a hint of what they are supposed to do and where to do it.

Built and installed the coop door. The rope is pulled from the front to open the door and is hooked on to a cleat to keep it open. We leave it open most of the time, closing it during very windy or cold nights. I used some furniture slides on the door inside the track to help it move easily.

Close up of the door. When the door is closed it does extend a bit below the door opening to help prevent little racoon fingers from trying to open the door (in theory at least).

Here is the cleat for holding the door open.

We also hung a little child's rake on the outside and use this to help turn under the poop or spread new wood chips in the coop. Very handy!

We moved the girls in and they seem very happy.

Lessons Learned

- Double check length of your lumber, especially the longer pieces. The 12 foot and 14 foot pieces I got from the store were longer by almost two inches. Without catching this, the coop would not have fit on the footer.

- When squaring the footer use either the 3-4-5 triangle method or diagonal corner method. Both of these methods assume that your opposite sides are equal in length for the rectangle to be square.

- Getting help framing is always nice. Having an extra pair of hands makes holding things in place much easier. If you are going it alone, then don't hesitating in generous use of clamps and temporary alignment guides.

- The chicken coop ramp's rungs are made of 1x2 on 6 inch centers. The girls seem to skate down between rungs, maybe a little closer together would have been better. They don't seem to mind and go in and out the coop all the time. I'll keep an eye on this to see if it becomes an issue. If you are moving your chickens when they are smaller, then build a ramp with closer rungs. After they mature you can swap out the ramps.

- I did add a removable board across the coop door to hold the shavings in when we open the door. It's held in place by a piece of 1x2 on each side of the coop and it slides up for removal.

- Don't think that because someone works at a big box home supply store they know everything you need. I ran into issues when ordering the roof for the coop. I went in and asked their special projects desk person for assistance in ordering everything I needed for an 8 x 14 foot metal roof. After I picked up all the parts I went online to the manufactures web site to see if they had any special instructions. After finding their installation guide, I quickly realized I was missing half the parts required to complete the roof they way I had explained it to the salesperson. It's better to take some time and research exactly what you will need before you go to the store, than it is having to wait 2 more weeks to get the rest of the parts delivered.

- Pre-drilling holes for nails and screws makes things much easier when you are working on top of a ladder.

- If you have young children like we do who want to collect eggs from the nesting boxes, then top opening boxes may not be the best bet. We had to put a step stool out by the coop so the kids could open the boxes and reach the eggs. I wouldn't lower the boxes any, but I might consider making a back door instead of the top opening. Just a thought.

- I love the slanting floors of the nesting boxes and the coop. Remember to factor that slope in when building your walls. Double check all your measurements and calculations. Also installing the walls is another great time to ask for a little assistance.

I'm really happy how things are going so far. I'll keep you posted as we progress.

Update - October 2012

It's been almost a year since we moved the girls into the coop. I am pleased to say things have been going wonderfully. We have since added 5 more hens to our flock doubling it to a total of 10. We are in the midst of planning the "in-law" expansion to the palace. I am hoping to get started shortly after the soil dries out a little bit more. (We had a extremely we summer season here on the West Coast of Florida.) Good news is the drainage system and raised floor kept the girls feet dry and out of any standing water. Sure the sand got wet from the blowing rain, but the water would drain through the sand and dry out even when there was standing water surrounding the coop.

Here are some replies to questions in the comments:

- I did cut the hardware cloth. I removed approximately a 2" x 2" square out of each corner. This allowed the cloth to slide inside like a tab. I trimmed the squares so it fit well between the uprights on the top and bottom.

- The project took longer that I had expected, but that has probably more to do with how much time I was able to put in on it consistently. Here is the rough break out of time:

2 Days - Foundation form and concrete pouring (plus 7 days to cure).

2 Days - Drainage and rock transfer.

4 Days - Painting & rough Carpentry .

2 Days - Screening, painting and installation of outer framing pieces.

1 Day - Building, installing and painting the nesting boxes.

4 Days - Building, installing and painting walls.

1 Day - Installing roof sheathing and building, painting and installing gutter.

1 Day - Installing metal roof (Very Long Day)

2 Days - Finish Carpentry, Hardware Installation and Painting

1/2 Day - Putting in sand.

Most days were 6-8 hours of work by myself. Having a second person might speed it up some, but won't cut the time in half. Paint (or stain) still needs time to dry. But some time might be saved by painting or staining everything after the project is up. Just ensure any wood that will be in contact with the footing is properly treated. Keep in mind that if you are rushed for time, you can adjust your build plan and get the hens in sooner to an unfinished coop. We did this because we didn't have all the parts for the roof and were waiting two weeks. We decided to move the hens in without the metal roof on. We did have the sheathing up to provide some shade.

- I didn't put together a materials list for the full project yet. I can give you some ballpark figures from what I remember:

2 - 14' 2x4's

6 - 12' 2x4's

50 - 8' 2x4's

9 - 92" 2x4 wall studs for roof beams.

~20 - 8' 1x2 furring strips (cheaper than normal 1x2's)

~30 - 8' 1x4 furring strips for trim work and roof (these were had rounded edges and were cheaper.)

1 - 3/4" 4'x8' plywood for floor

4 - 1/2" 4'x8' plywood for roof sheathing

6 - 4'x8' shipboard siding (a lot was wasted and could have been used for nesting boxes.)

4 - 3/4" 16"x48" craft boards for nesting boxes.

1 - 6' 1x10 for ramp

1 - 1/4" 2'x2' plywood board for door.

1 roll of 3' wide 1/2" hardware cloth.

3 rolls of 2' wide 1/2" hardware cloth.

6 large hinges for doors and nesting box cover

6 small hinges for window covers.

2 heavy duty latches for doors

4 buckle hinges for window covers and nesting box latches

10' small link black chain

6 small snap latches to keep door locks closed and window covers open.

2 metal plant hangers for feed and water

4 metal eye hooks for chicken ramp

5 larger metal eyes for door rope guides

15' small white rope

Various gutter pieces to make 14' gutter with downspout and end caps.

10 - gutter mounting clamps.

1/2 cubic yard of granite rock for sub floor

1 cubic yard of sand for run floor

1 role of 3' wide weed barrier cloth

linoleum for coop and nesting box floor

16d Galvanized Nails for framing

10d Galvanized Nails for toe nailing framing

8d Galvanized Nails for joining 2x4's together back to back

1 3/4" Outdoor screws to join trim and plywood to 2x4's

2 1/2" Outdoor screws to join 2x4's together (eg to sandwich hardware cloth)

1 3/4" Galvanized Roofing Nails

pop-rivets for gutter

Gutter sealant

2 cans spray paint for gutter

paint for coop

roof material and parts.

*** I'm sure I have overlooked some of the parts. Use nails for framing as they are good against shearing and use screws where you want to pull things together tightly like out framing and walls to studs. If your husband is proficient toe nailer then the roofing beam plates I used aren't needed.