Hope you folks don't mind me adding from another post of mine...

Leahy Manufacturing Company

Higginsville, Missouri

Established 1883 1983

The Past to the Present Incubators By: Kevin Roth

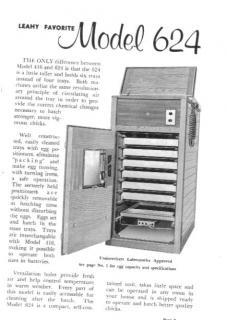

As many of us have found the hobby of raising backyard chickens, certain research has to be done before one starts out. My search has found two valuable resource of gaining knowledge on raising poultry; the magazine Backyard Poultry and the website: backyardchickens forum. My journey of learning raised my interest in incubators and the components used in manufacturing them.

I also went to craigslist, which caused me more excitement than a room filled with helium party balloons when I found and purchased a Leahy Favorite Incubator Model 1200. I had never owned an incubator and being a backyard cabinet maker, I decided to bring new life to this unit by restoring it. Nothing on todays incubator market matches the craftsmanship, design and construction that these units have. What incubator manufactured today will last 40 plus years and still produce high incubation rates? This company made thousands of these incubators and many are still in use today. Ive heard where people have found them in old barns, at auctions and family hand me downs. Some of these people are using them as coffee tables and dont know what they have or how to use them.

To learn more about this company, my journey directed me to a man in Minnesota that restores incubators, he called these units the Cadillac of Incubators and nothing on the market today is built so well. Words like that only added fuel towards my desire to learn more about the company. My research travels directed me towards the Show Me State Missouri, specifically Higginsville where the company was headquartered. Here I linked up with the Higginsville Historical Society and Ms Loberta Bobbie Runge. She has provided me with newspaper articles; photos and company pamphlets to assist me in writing this article. I also found that Brad Legg of Legg Peafowl Farm located in Kansas City, Mo uses the model 1200 exclusively because of the high hatch rate the 14 incubators give him. On his web site you can down load the original operators manual for the incubator.

Richard B. Leahy in 1867, being raised in New York on the shores of the Atlantic, was a ten year old boy who had earlier lost his mother and now had to deal with loosing his sea captain father to drowning. For the next 11 years he followed his fathers love for the sea, starting out being a cabin boy. Having the opportunity to visit many different countries gave him a diverse education. In 1883 Mr. Leahy headed west, landing in Higginsville to make his home with a new bride. Starting off in a small 14 x 20 shop with one foot powered saw, he began manufacturing beehives for a local farmer. The business started to grow and in 1888, with financial help from James E. Gladish, the inventions and product they made where greatly accepted in the bee industry.

Page 2

Leahy Manufacturing Company By: Kevin Roth

Higginsville, Missouri

Mr. Gladish wife was very fond of Leghorn Chickens and it was probably her interest and persuasiveness that directed the company to diversify and start manufacturing redwood incubators in 1905. Their employees where all master cabinet makers with strong work ethics and it showed in the quality and craftsmanship in their products.

The incubator was made using 2 layers of tongue and groove. The outside was Redwood, divided by an air space and Celotex moisture barrier. By utilizing redwood in both the bee hives and incubators required the company to receive by rail, 65 carloads of lumber per year. Rapid growth found it necessary to incorporate the business in 1890 as the Leahy manufacturing Company, with capital investment of $12,500.00, employing 25 men and in busier months running two shifts with 150 men. During those months, it was never a question if they would receive orders, rather if the orders could be filled in a timely manner. The large safe in the office was testimony of the required cash on hand and at times held more money than all the banks in Higginsville. It was a good thing the bank robbers, Bonnie and Clyde, never caught wind of this loot.

Over time, Mr. Leahy became the authority of Bee Keeping in the United States, capturing 90% of the beekeeping business. They shipped bee supplies and incubators worldwide. Leahy Incubators where shipped to Australia, Cuba, India, Peru and thru the United Nations. They had contracts to provide both Sears and Montgomery Wards with incubators thru catalog sales. In 1927 Sears Roebuck was shipping 30,000 incubators each year and the company expanded with a new two story, 30 x 80, equipped with Grinnell Sprinkler System

In 1905 Mr. James E. Gladish bought Mt. Leahys interest in the company. Mr. Leahy died in 1906 at the age of 49.

Although the company bares the Leahy name, it was the four generations of the Gladish family that provide the capital, managerial skills, longevity and vision for the company to prosper over the years. And let us not to forget, behind every good man there is a greater woman, Margaret Gladish was the company bookkeeper in 1908 and held the position for 64 years.

Page 3

Leahy Manufacturing Company By: Kevin Roth

Higginsville, Missouri

The company converted their machinery from steam power to electricity in 1912. The plant produced its own electricity from a diesel powered generator; it was the first electricity to be used in Higginsville.

The business was sold in 1978 to James Sopczyk (pronounced subject) who already had been selling bee keeping supplies in Minnesota. His enthusiastic attitude inspired the now failing company to make a last stand at producing a quality products. Retired employees came back to offer their expertise, rekindling the spark for success for the first few years under the new ownership. But no one could have anticipated that the commercial beekeepers would sell out their equipment at bargain prices; half of the company was now starting to die. By 1981 the incubators were keeping the business afloat, showing $80,000 in gross profits in 1983. Mr. Sopczyk believed the incubators alone would have made a good business, but the bank wouldnt sell it separately. The end result being the doors closed for the last time December 1983, falling just months short of 100 years in business. The bank scheduled the auction of the machinery and anything else that wasnt nailed down in July of 1984. The old building sat vacant, a monument to the past, dedicated to talented employees over the past 100 years, demolition of this building however was in 1993.

These are well crafted incubators that have withstood the test of time, with all components still readily available today. OK, I hear you folks that are talking about electronic controlled thermostats apposed to the wafer. Allow me to ask, how many chickens have been hatched using the wafer thermostat in the past 100 years? Todays hobbyist seem to be looking for the set and leave it alone incubators, not the tried and true. These jewels are really a beautiful piece of furniture with the capabilities to bring new live into this world.