Though mine is a Brower - or Humidaire made in partnership with Brower, I've had a good LOOK at the innards and OH YEAH, two layers of heart tongue and groove mature redwood alone would hurt a builder's budget and throw it clean out of the hobby market.

That quality redwood is VERY hard to find now and wouldn't be available in production sized amounts. A hobbyist could dig it up for a single project, just at significant cost... That redwood was COMMON in the 1800's and early 1900's but what is now available is significantly poorer quality wood with much more sap wood than heartwood. And heartwood is what lasts in a humid application like an incubator.

While the electrical element, the snap wafer and humidity pan wouldn't run much - it does add up. If you update to automatic humidity, or an electronic thermostat that price bumps up again.

Wood available today is NOT and cannot be the same grade they were using. If lesser quality wood then you either have to treat it, or use an interior layer of technical materials for insulation. Both of which add cost. Whether it's time or materials.

Treatment has to be considered carefully. VOC's are going to be an applicable concern where eggs are being incubated. Low VOC sealers tend to cost more and are less elastic(won't last as long in an incubation application) than the higher VOC spar varnishes. Spar varnishes would require quite a long in place drying time to have the VOc's drop to safe levels for incubation - time = more money.

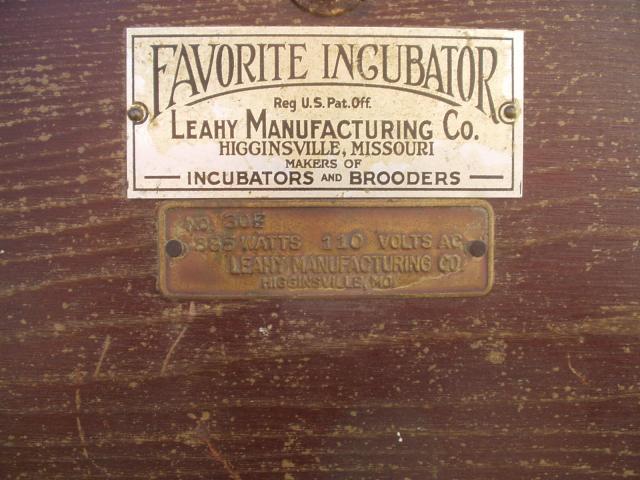

They're great incubators if you can find them and rehabilitate them but replicating the quality with wood available today would be nearly impossible. You could make a look alike but then you'd be recreating the Dickey.