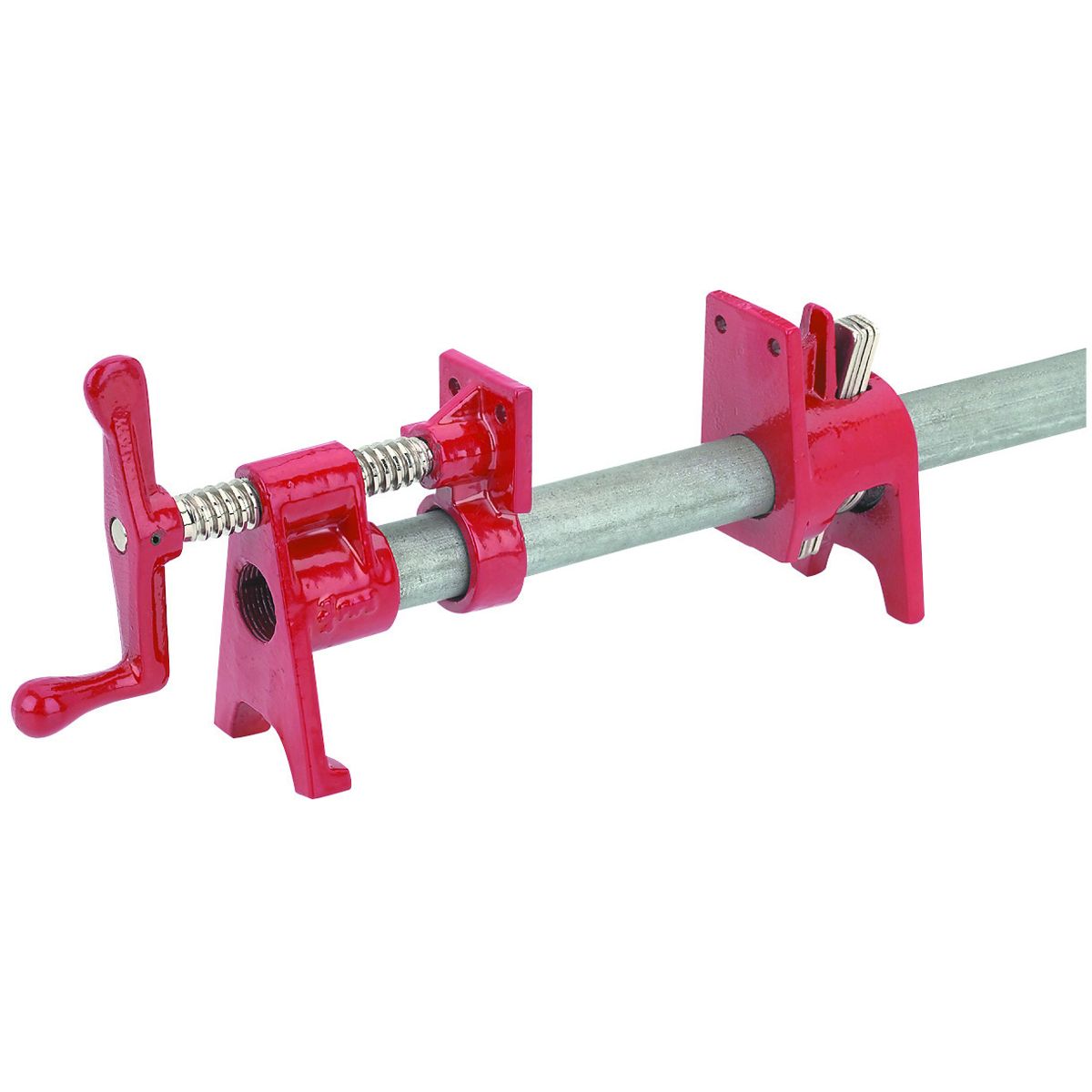

Just an update on putting together my pipe clamps for use maybe to build some pallet wood glue-up panels this summer. For anyone not familiar with pipe clamps, they look like this....

You buy the two end clamp pieces in a kit and then you have to buy the pipe separately. Over the past few months, I bought two pipe clamp kits at Harbor Freight using a 30% off coupon when they were available. Yes, it took me two months to buy two kits because you can only use one coupon per day. I don't live in town, and typically only drive to town about once a week. So, I had to wait for the 30% off sale to come around again. For me, it was worth the wait because I cannot do any glue-ups in the garage until it gets over 65F. Currently, our nights are about 3F, so my unheated garage is not very warm.

Today, I bought the pipe for the clamps. I went to our local Home Depot, because they can cut and thread the pipe in the store. I talked to a young man at the HD and told him I was putting together some pipe clamps and wanted him to cut a 10-foot pipe for me into (2) 3-foot sections and (2) 2-foot sections and then thread the ends.

Well, he did not know anything about pipe clamps, but he asked me why I just did not want to buy the pipe sections already cut to length. So, I pointed out to him that the precut pipes would add up to over $70.00, whereas I could buy a 10-pipe for only $30.00 and have it cut up into four pieces and threaded for the clamps.

Unfortunately, he was not very experienced with the pipe cutting and threading machine. After he cut the pipe and threaded it, I asked him to check the threads with a pipe coupler that I was going to buy. Good thing I thought of that while in the store. Turns out that his threading of the pipes was off and the pipe coupler would not screw on. Obviously, a problem.

Without getting upset, I told him that the threads had to work for the clamps or they had no value to me. He was at a loss, so I suggested he ask someone else in the store that maybe had more experience. He found a manager who knew how to operate the machine, she could see that the threads were too large to accept the coupler, so she dialed in the machine to cut the threads deeper into the pipe. Then, everything worked just fine.

Boy was I glad I had him check those threads before I left the store!

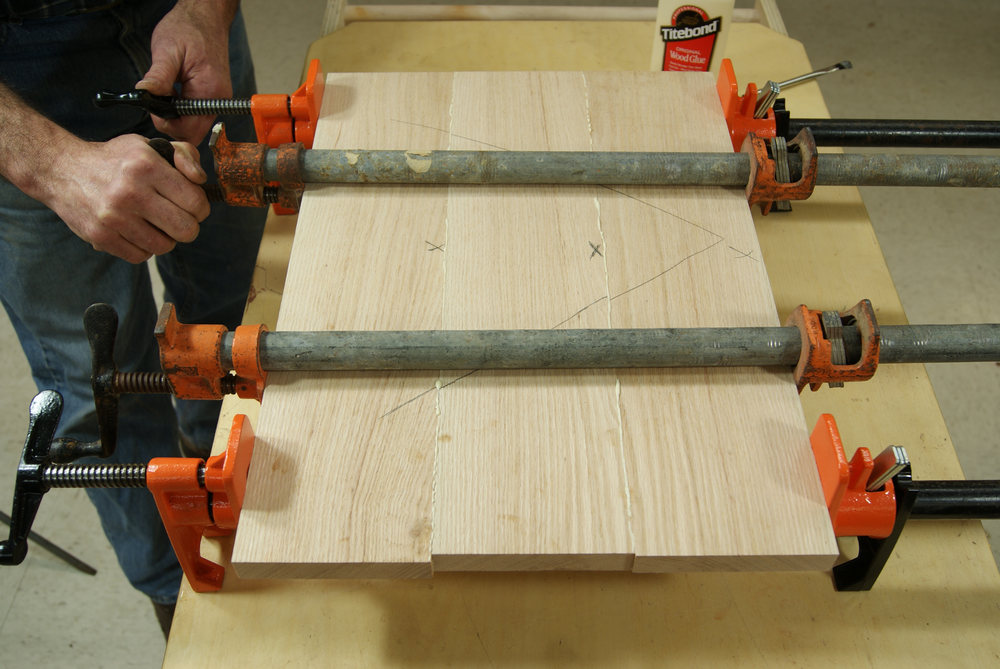

If you are wondering what a panel glue-up looks like, here is a picture...

I plan on trying this out this summer using pallet wood slats to see if I can make some nice panels for some projects. I'll have to up my woodworking skill level, but it's something I have wanted to learn.

Guess what I just picked up? Yep, a pallet with the top pallet slats covering the entire top! Exactly what I was thinking I would need for the platform. Pallet looks like this...

Guess what I just picked up? Yep, a pallet with the top pallet slats covering the entire top! Exactly what I was thinking I would need for the platform. Pallet looks like this...

I guess this one will fall into the easiest ever pallet projects! It is just surprising how a person can pick up a one-off type pallet and immediately think of a use for that special build.

I guess this one will fall into the easiest ever pallet projects! It is just surprising how a person can pick up a one-off type pallet and immediately think of a use for that special build.

Just an update on putting together my pipe clamps for use maybe to build some pallet wood glue-up panels this summer. For anyone not familiar with pipe clamps, they look like this....

Just an update on putting together my pipe clamps for use maybe to build some pallet wood glue-up panels this summer. For anyone not familiar with pipe clamps, they look like this....

Love that idea! Just took out one of my T25 star bits and used the impact driver to unscrew all the screws. The pallet came apart with no effort. I ended up with (3) 48-inch long 2X4's and (12) 40-inch long 2X4s. All in great condition. Practically new. No nails or anything to worry about in those boards. They are ready to use as is or to cut on the saw to size without concern of hidden broken off nails.

Love that idea! Just took out one of my T25 star bits and used the impact driver to unscrew all the screws. The pallet came apart with no effort. I ended up with (3) 48-inch long 2X4's and (12) 40-inch long 2X4s. All in great condition. Practically new. No nails or anything to worry about in those boards. They are ready to use as is or to cut on the saw to size without concern of hidden broken off nails. An unexpected bonus was that the screws came out in perfect condition. They look almost brand new. All in all, I got one pound of 3-inch T25 exterior deck screws out of the pallet that I can use on some other project. Just a quick look at Menards, that one pound of those screws alone costs $7.98.

An unexpected bonus was that the screws came out in perfect condition. They look almost brand new. All in all, I got one pound of 3-inch T25 exterior deck screws out of the pallet that I can use on some other project. Just a quick look at Menards, that one pound of those screws alone costs $7.98.

I can celebrate the small things in life. Hope some of you can appreciate that, too. Later...

I can celebrate the small things in life. Hope some of you can appreciate that, too. Later...

I haven't decided what type of design I will use for the seed starting shelf. So, I just keep banging apart some pallets hoping that inspiration will hit somewhere along the line! Maybe a stack of pallet wood ready to be used will speak to me?

I haven't decided what type of design I will use for the seed starting shelf. So, I just keep banging apart some pallets hoping that inspiration will hit somewhere along the line! Maybe a stack of pallet wood ready to be used will speak to me?