Quote:

I understand what he was thinking when he said to use 2 diodes. But it wont work. You have power hooked to the same terminal as the ground of the other adapter. You dont have power back feeding in to the other adapter. Its feeding forward from one hot to the other ground. If you block that with a diode the you also block forward flow from its on hot wire.

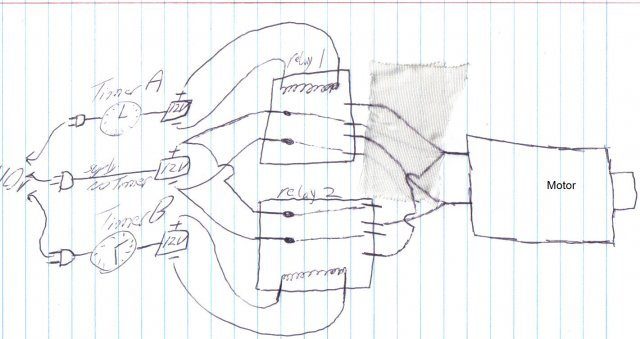

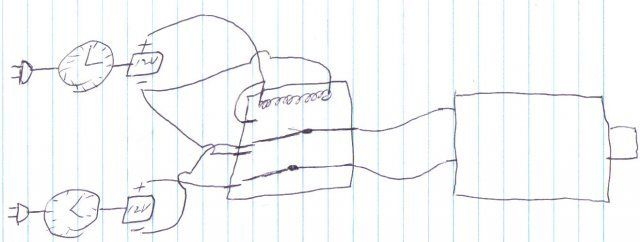

If you used two separate batteries wired threw relays then it may work. Use the same wiring you have now to power the relays in place of the motor. The relays then connect the hot (and ground if ya get duel pole relays) wire from the battery to the motor. Because the battery's are separate systems it should work.

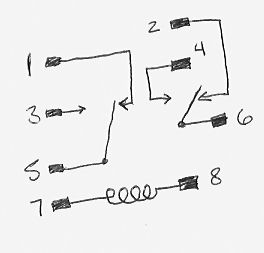

If you use 2 dual pole relays to power the motor so you are switching both the power an ground then you could run it off one power source.

I understand what he was thinking when he said to use 2 diodes. But it wont work. You have power hooked to the same terminal as the ground of the other adapter. You dont have power back feeding in to the other adapter. Its feeding forward from one hot to the other ground. If you block that with a diode the you also block forward flow from its on hot wire.

If you used two separate batteries wired threw relays then it may work. Use the same wiring you have now to power the relays in place of the motor. The relays then connect the hot (and ground if ya get duel pole relays) wire from the battery to the motor. Because the battery's are separate systems it should work.

If you use 2 dual pole relays to power the motor so you are switching both the power an ground then you could run it off one power source.