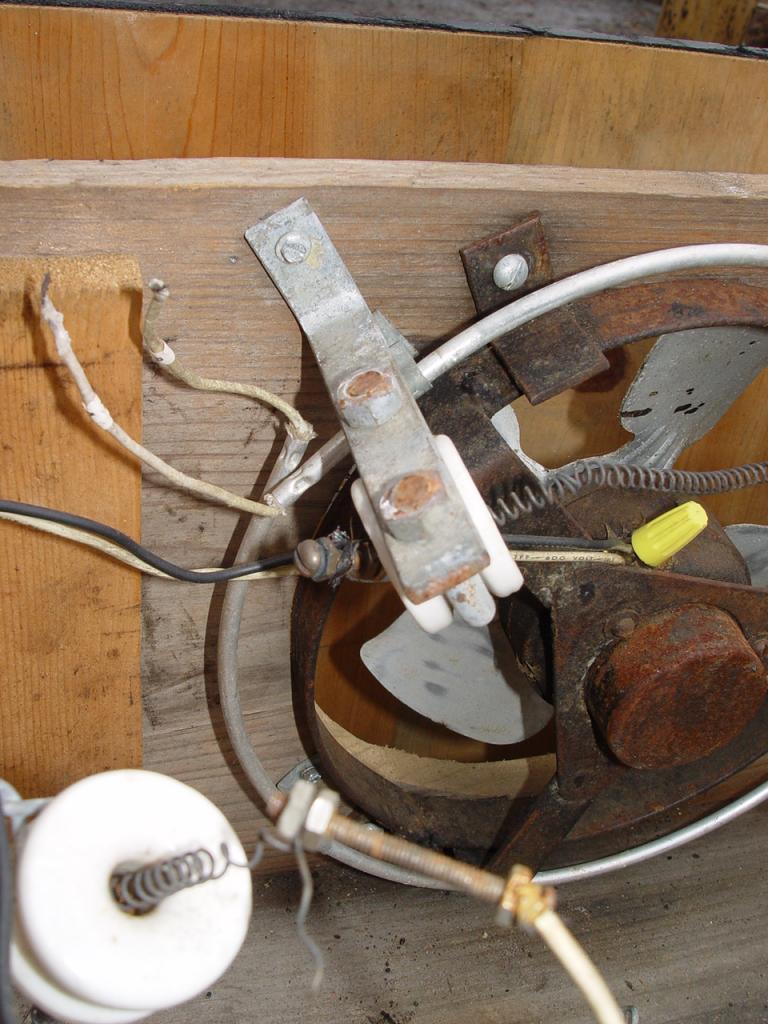

I want you to do something for me. first unplug the incubator. Look at the wire where it is connected to the plug, it's black and probably as big around as a pencil. Follow this pencil sized cord to where there isn't anymore black, and you will see one black wire and one white wire. There may be a green but right now we won't worry about it. The small black and white wires are called the conductors. The black wire carries the voltage from where it's plugged in, and the white completes a path to ground allowing current flow and making things work. If either one of these wires is unhooked, broken, burnt, for whatever reason, things don't work. Follow the small black wire around the incubator, and write down everywhere it hooks to something. Do the same with the white. I noticed in some of the pics that some places the wire is attached to something with a screw, this is called a termination point, other places where the wires are hooked together with colored plastic things, these are called wire nuts. Follow both the white and black wires through the incubator noticing where the wires are terminated, they all should be tight, the colored ones can be unscrewed my hand by holding onto the wires, and turning the wire nut. the others may need a screwdriver and a pair of pliers. If everything is tight plug the thing in and give it time to work, the coil may take time to turn red, the fan may or may not come on right away, but give it time. The light on the front may just be an indicator light telling you that the thing is plugged in, or it comes on and off with the wafer as the coil is hot. Don't be afraid to leave it plugged in for awhile, The coil may smoke alittle and smell bad, but as long as there's no fire,and the breaker or fuses didn't pop, the fan should run, the wire will get red, and maybe if things get the right temp. the wafer will shut things off. Give it a try. DON'T TOUCH ANYTHING AFTER YOU PLUG IT IN, KEEP YOUR HANDS OUT.