Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

***OKIES in the BYC III ***

- Thread starter Buckguy20

- Start date

Quote:

The ventilation is not used to control humidity in a cabinet incubator, if your humidity is too low add a sponge or two to your water tray, teh ventilation is critical proper temp balance and fresh air for the developing eggs.

Hope that helps, it will dramitically improve your incubation and hatching success.

With the automatic bucket the humidity stays the same unless it rains. The incubator had a small tray with float in it, the humidity was always too low! Ordered the newer tray & then I struggle with the humidity being too high, since the new trays are larger. Since I have the larger pan the humidity stays @ 45%. I keep the 6 vents open about 50% should I open them more? When the humidity was real high in the air-- mid august. I had the vents opened all the way & that help keep my humidity down.

The ventilation is not used to control humidity in a cabinet incubator, if your humidity is too low add a sponge or two to your water tray, teh ventilation is critical proper temp balance and fresh air for the developing eggs.

Hope that helps, it will dramitically improve your incubation and hatching success.

With the automatic bucket the humidity stays the same unless it rains. The incubator had a small tray with float in it, the humidity was always too low! Ordered the newer tray & then I struggle with the humidity being too high, since the new trays are larger. Since I have the larger pan the humidity stays @ 45%. I keep the 6 vents open about 50% should I open them more? When the humidity was real high in the air-- mid august. I had the vents opened all the way & that help keep my humidity down.

Quote:

Glad you were able to get half of them to hatch! First time DD used a foam bator she only had 4 hatch out of 4 dz!!!

Usually doesn't take 4 days for all to hatch. I would say it could be a temperature issue. When using my sportsman I have had issues with eggs not hatching on time, since the temp varies throughout the cabinet. I turned the temp up a degree in hopes that this hatch comes out on time.

Were you using an autoturner? Think auto turners help BUNCHES!

The leg problems could be do to the late hatching.

Sorry! I didn't consider where eggs came from-- since most of mine come from our birds!!! Have had bough eggs hatch before I even put birds on lockdown!! Never had bought eggs hatch late.

I used a styrofoam incubator with fan and auto-turner. They were all alive on the 18th day. I think maybe my lovely young children might have gotten into it and left the lid off too long, not sure. My humidity levels would only stay in the 50's no matter what I put in there, maybe that was the cause. I opened a few of the dead ones and it appeared that they had that "shrinkwrap" affect. I almost threw one out this morning that thankfully I put it up to my ear and I heard scratching and peeping. Needless to say I did get antsy with that one because it hadn't even pipped the shell. I helped it out this morning and it's fine. I learned alot this time, next time will be easier for me I hope. I was more excited than my kids...lol

Glad you were able to get half of them to hatch! First time DD used a foam bator she only had 4 hatch out of 4 dz!!!

Usually doesn't take 4 days for all to hatch. I would say it could be a temperature issue. When using my sportsman I have had issues with eggs not hatching on time, since the temp varies throughout the cabinet. I turned the temp up a degree in hopes that this hatch comes out on time.

Were you using an autoturner? Think auto turners help BUNCHES!

The leg problems could be do to the late hatching.

Sorry! I didn't consider where eggs came from-- since most of mine come from our birds!!! Have had bough eggs hatch before I even put birds on lockdown!! Never had bought eggs hatch late.

I used a styrofoam incubator with fan and auto-turner. They were all alive on the 18th day. I think maybe my lovely young children might have gotten into it and left the lid off too long, not sure. My humidity levels would only stay in the 50's no matter what I put in there, maybe that was the cause. I opened a few of the dead ones and it appeared that they had that "shrinkwrap" affect. I almost threw one out this morning that thankfully I put it up to my ear and I heard scratching and peeping. Needless to say I did get antsy with that one because it hadn't even pipped the shell. I helped it out this morning and it's fine. I learned alot this time, next time will be easier for me I hope. I was more excited than my kids...lol

Quote:

The ventilation is not used to control humidity in a cabinet incubator, if your humidity is too low add a sponge or two to your water tray, teh ventilation is critical proper temp balance and fresh air for the developing eggs.

Hope that helps, it will dramitically improve your incubation and hatching success.

With the automatic bucket the humidity stays the same unless it rains. The incubator had a small tray with float in it, the humidity was always too low! Ordered the newer tray & then I struggle with the humidity being too high, since the new trays are larger. Since I have the larger pan the humidity stays @ 45%. I keep the 6 vents open about 50% should I open them more? When the humidity was real high in the air-- mid august. I had the vents opened all the way & that help keep my humidity down.

Unfortunately it is impossible to tell you which vents to open or close down, it is completely based on where the incubator sets, how close it is to walls (that affects air flow), and what the environment is where the incubator sits.

if it were me, i would take and measure the temperature in each tray, monitor what th ehigh temp is, and what teh low temp is in each tray, write down teh results for each tray. Open the fresh air intake all the way, then re-measure all the trays, adjust the exhaust vents one at a time measuring tray temps each time you make an adustment, allow at least 30 minutes between making an adjustment and measuring the temperature.

Do not adjust the temperature during this process the goal is to get all the trays in balance.

Once the ventilation is set all teh trays will have the same temperature, same rise and drop.

Set the inc. temperature at that point allow at least 30 minutes from making a temp adjustment and checking to see if you need to re-adjust.

Once temp is set you will likely have humidity without any sponges around 30-35% possibly a bit higher based on where teh incubator is, wash rooms and bathrooms are always more humid.

Incubation humidity I have my best luck between 45-47% and hatch around 75%.

I have walked several thorugh this process and everyone gets a better hatch and more balanced incubator when done but it does take a full day to get the ventilation alone set right.

I use a HVAC thermometer for this it is accurate to 1/10 of a degree and takes a new reading every 2 seconds, you can listen to incubator to know when teh lement is coming on and going off. This is a lot of work but you only need to do it once so long as you are not moving your incubator. I do the same thing with our hatcher which is an old redwood leheay manufacturing built back in the 40's and I have it dialed in to less than than 3/10s of a degree temp swing and all trays perfectly even on temp and temp swing.

The ventilation is not used to control humidity in a cabinet incubator, if your humidity is too low add a sponge or two to your water tray, teh ventilation is critical proper temp balance and fresh air for the developing eggs.

Hope that helps, it will dramitically improve your incubation and hatching success.

With the automatic bucket the humidity stays the same unless it rains. The incubator had a small tray with float in it, the humidity was always too low! Ordered the newer tray & then I struggle with the humidity being too high, since the new trays are larger. Since I have the larger pan the humidity stays @ 45%. I keep the 6 vents open about 50% should I open them more? When the humidity was real high in the air-- mid august. I had the vents opened all the way & that help keep my humidity down.

Unfortunately it is impossible to tell you which vents to open or close down, it is completely based on where the incubator sets, how close it is to walls (that affects air flow), and what the environment is where the incubator sits.

if it were me, i would take and measure the temperature in each tray, monitor what th ehigh temp is, and what teh low temp is in each tray, write down teh results for each tray. Open the fresh air intake all the way, then re-measure all the trays, adjust the exhaust vents one at a time measuring tray temps each time you make an adustment, allow at least 30 minutes between making an adjustment and measuring the temperature.

Do not adjust the temperature during this process the goal is to get all the trays in balance.

Once the ventilation is set all teh trays will have the same temperature, same rise and drop.

Set the inc. temperature at that point allow at least 30 minutes from making a temp adjustment and checking to see if you need to re-adjust.

Once temp is set you will likely have humidity without any sponges around 30-35% possibly a bit higher based on where teh incubator is, wash rooms and bathrooms are always more humid.

Incubation humidity I have my best luck between 45-47% and hatch around 75%.

I have walked several thorugh this process and everyone gets a better hatch and more balanced incubator when done but it does take a full day to get the ventilation alone set right.

I use a HVAC thermometer for this it is accurate to 1/10 of a degree and takes a new reading every 2 seconds, you can listen to incubator to know when teh lement is coming on and going off. This is a lot of work but you only need to do it once so long as you are not moving your incubator. I do the same thing with our hatcher which is an old redwood leheay manufacturing built back in the 40's and I have it dialed in to less than than 3/10s of a degree temp swing and all trays perfectly even on temp and temp swing.

Last edited:

Quote:

Thanks! I'll make sure that's on the auction list

Thanks! I'll make sure that's on the auction list

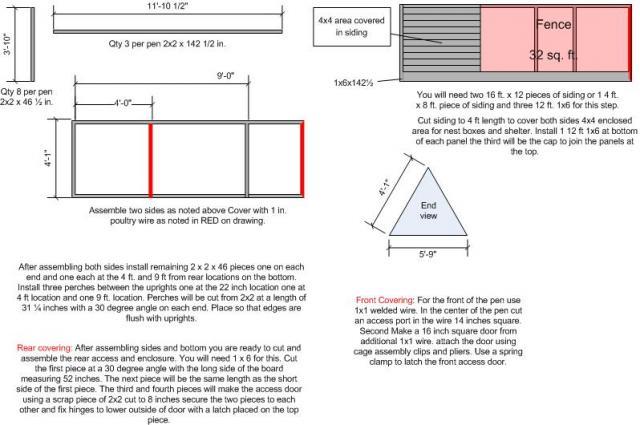

Hay Jarvis think I might be able to talk you into giving me the measurements for thouse teepee style pens you got. I sure like the looks of them.

Quote:

Send me an e-mail and i will send you the complete plans..

Send me an e-mail and i will send you the complete plans..

Quote:

The ventilation is not used to control humidity in a cabinet incubator, if your humidity is too low add a sponge or two to your water tray, teh ventilation is critical proper temp balance and fresh air for the developing eggs.

Hope that helps, it will dramitically improve your incubation and hatching success.

i failed to add, once the ventilation is set correctly you have no variation in tray temps what so ever, and a decreased low to high temp swing as well. You can often see a 1.5-2.5 degree temp swing from the time one turns on till it turns off then additional 1/2 a degree or more as teh element cools back off, once the ventilation is set perfectly all teh trays will be balanced, and temp swing will be 1/2 degree or less from on to off. It makes a huge difference but often takes 8-10 hours to get set perfectly. Make sure you are not using it when setting it, though. Once the ventilation is set right then you can properly adjust the temp, once temp is set adjust the water tray by adding or removing incubation sponges until is right as well. one step at a time and you will get it right.

My incubator is pretty good sized but I have my water bowl in the bottom under one of the small fans that keep air moving it does okay keeping the humidity around the 50% for the first 18 days then I used a wire coat hanger to drape an old cotton sock over it, it wicks water up and in front of the fan and the humidity will run about 75-80% that has been good for me the only issue I have had is losing too much once I start opening the door to get the new chicks out some of the late hatching eggs have dried out a bit that's why I'm thinking about building a seperate hatcher, one thing I do know for sure is that I'm still learning from all these posts from people that know a lot more about this than me LOL

The ventilation is not used to control humidity in a cabinet incubator, if your humidity is too low add a sponge or two to your water tray, teh ventilation is critical proper temp balance and fresh air for the developing eggs.

Hope that helps, it will dramitically improve your incubation and hatching success.

i failed to add, once the ventilation is set correctly you have no variation in tray temps what so ever, and a decreased low to high temp swing as well. You can often see a 1.5-2.5 degree temp swing from the time one turns on till it turns off then additional 1/2 a degree or more as teh element cools back off, once the ventilation is set perfectly all teh trays will be balanced, and temp swing will be 1/2 degree or less from on to off. It makes a huge difference but often takes 8-10 hours to get set perfectly. Make sure you are not using it when setting it, though. Once the ventilation is set right then you can properly adjust the temp, once temp is set adjust the water tray by adding or removing incubation sponges until is right as well. one step at a time and you will get it right.

My incubator is pretty good sized but I have my water bowl in the bottom under one of the small fans that keep air moving it does okay keeping the humidity around the 50% for the first 18 days then I used a wire coat hanger to drape an old cotton sock over it, it wicks water up and in front of the fan and the humidity will run about 75-80% that has been good for me the only issue I have had is losing too much once I start opening the door to get the new chicks out some of the late hatching eggs have dried out a bit that's why I'm thinking about building a seperate hatcher, one thing I do know for sure is that I'm still learning from all these posts from people that know a lot more about this than me LOL

Here is a quick shot of our set up, the hatcher (smallest one) has 6 trays that will hold 100 + bantam eggs per tray.. The other two are incubators they are nearly as tall as I am.

This room only serves the incubators, hatcher, chicks for 8 hrs, and egg storage, and misc. supplies.

This room only serves the incubators, hatcher, chicks for 8 hrs, and egg storage, and misc. supplies.

well I guess when I kill a thread, I really kill the thread. Thanks to elwood for bringing it back. I hope it doesn't go another 3 hrs. without a post.

New posts New threads Active threads

-

Latest posts

-

Is it possible for a chicken to die from the stress of being chased?

- Latest: fowltemptress

-

Green Nostrils / weirdly shaped hen

- Latest: HorseGirlAbby

-

-

-

-

-

Latest threads

-

Wind chill doesn’t count, right?

- Started by Lulu-vt

- Replies: 8

-

-

-

-

Can my chickens catch the flu from humans?

- Started by -chook-

- Replies: 0

-

-

Threads with more replies in the last 15 days

-

-

Open Contest Cutest Couples Photo Contest—Poultry Edition

- Started by Lacy Duckwing

- Replies: 135

-

BYC's 52-week Photography Challenge. Week 2: (Jan 12-18, 2026). Theme: Flock Star

- Started by Lacy Duckwing

- Replies: 95

-

-

-

×