Microwave Incubator Build

Careless repair or modification of a microwave oven can result in death or worse. Experienced technicians have met their maker as a result of a momentary lapse of judgement while testing an oven with the cover removed. Microwave ovens are without a doubt, the most deadly type of consumer electronic equipment in widespread use. The power supplies for even the smallest microwave ovens operate at extremely lethal voltage and current levels. Do not attempt to troubleshoot, repair, or modify such equipment without understanding and following ALL of the relevant safety guidelines for high voltage and/or line connected electrical and electronic systems. |

Step 1. Gutted microwave

Got an old microwave oven (on freecycle). Made sure it had a functioning turntable.

Before doing anything, I read up on safe handling of microwave ovens. Unplugged the oven. Unscrewed exterior panels.

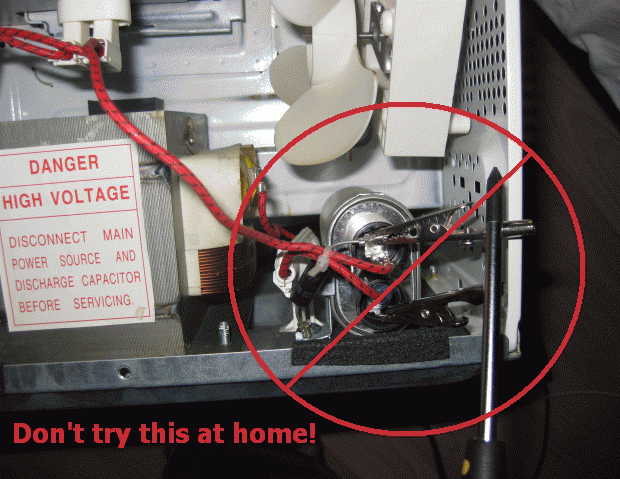

Discharged high voltage capacitor by shorting its terminals to the chassis, and then to each other. The discharge should be done through a high voltage resistor using a tool with a long (2') insulating handle. People who value their wellbeing do NOT discharge the capacitor using a screwdriver with an insulated handle because (a) it means standing right next to all the sparks and (b) the high current of the resulting discharge can weld the screw driver to the terminals. So my advice is DO NOT DO THIS:

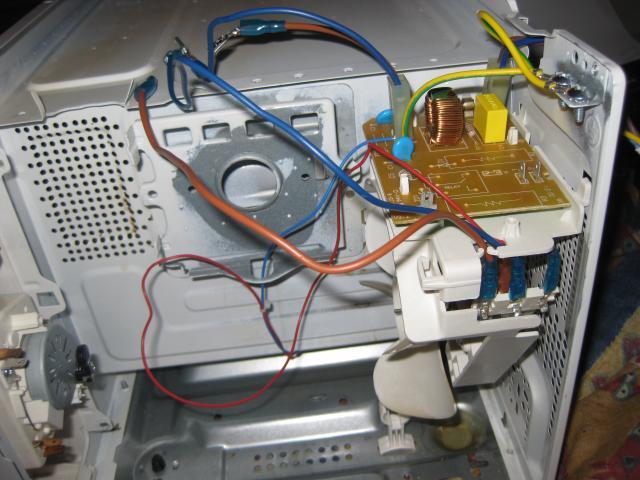

Removed high voltage components: transformer, capacitor, magnetron. On this occasion I did not bother to extract the powerful magnets from the magnetron.

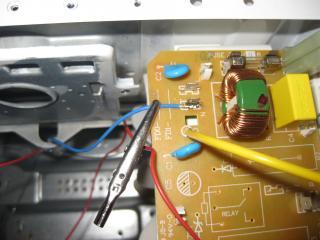

Inspected the turntable motor. This one took 30 VAC: the red live wire originated in the fan coil, so I had to keep the fan. Soldered the blue return wire to the neutral terminal on the noise filter PCB, which was located on top of the fan assembly. (You can see from the picture on the right that I had already unsoldered the components from the adjacent "soft start" circuit: I particularly wanted the mains relay.)

Gutted unnecessary wires, thermal sensors, light fitting, switches etc.

Parts List:

Microwave oven

I also needed:

Screwdriver

Capacitor discharge tool

Wire strippers/clippers

Soldering iron (25 W)

Solder (multicore 0.7 mm)

Next Step

Back to Microbator Plan