jennyinvermont

In the Brooder

- Apr 2, 2021

- 24

- 19

- 31

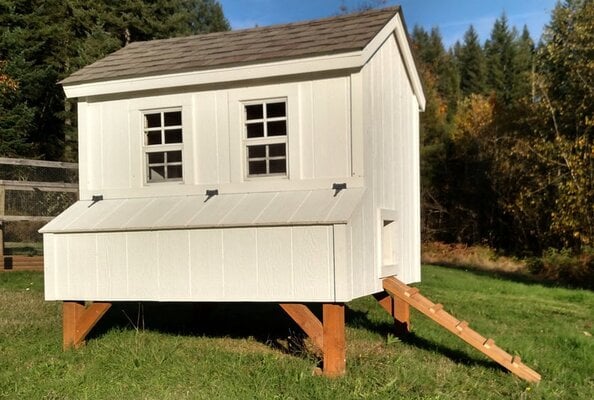

So we have a great plan for a coop we're building. We're swapping out the shingles for a metal roof (way cheaper, and easier). We've mostly heard we DON'T need the plywood under metal roof, but that seems weird to me? Won't hte plywood kind of seal the roof? But no plywood would add ventilation? We're thinking of doing a black roof but I feel like we NEED plywood underneath to block the heat? (We live in Southern Vermont, humid in summer but mostly really cold). Oh and yes, we're extending the roof - by ??? 3 inches on each side? Any recs?